Illustration

Gallery

Description

Application

Hydraulic (fluid) coupling are installed in heating installations in order to separate by means of hydraulics the boiler circulation and the heating circulation, aiming at improvement of operation and control effectiveness of such installation. If the coupling is selected appropriately, it works also as a mud trap.

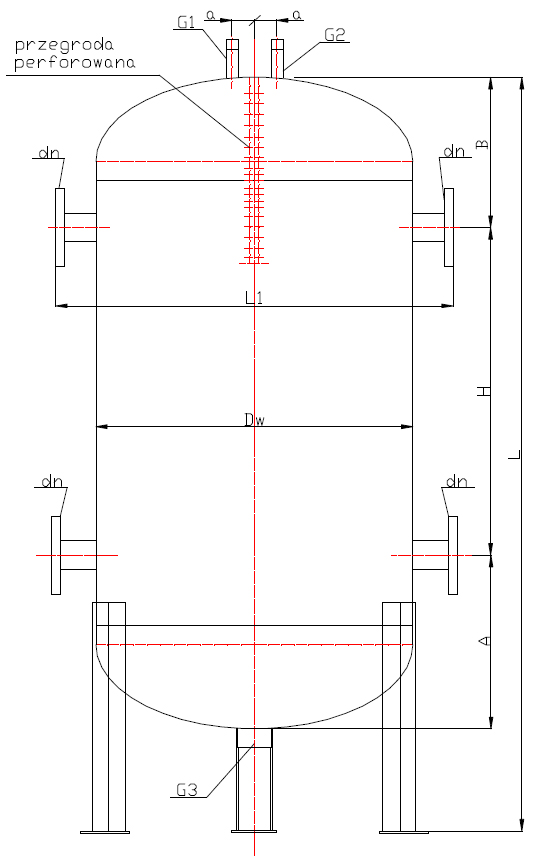

Construction

The hydraulic couplings are made of structural carbon steel and painted with a primer on the outside. Inside the tank, opposite the heating medium inlet, there is a perforated partition. The partition improves the flow direction and together with water flow rate decrease it boosts the deaeration effect. The tanks of dimensions larger than RH150/400 are produced as standing constructions, equipped with legs.

Note

Design Pressure= 0,6 MPa or 1,0 MPa Design Temperature To= 110oC

Dimension table

| Hydraulic (fluid) coupling type BRH | ||||||||||||||

| Type | DN | Dw | H | A | H1 | L | B | G1 | G2 | G3 | V | Optimal flow |

Power Max | Weight |

| Nominal diameter tubes |

Diameter coupling |

Total length tubes |

Spacing tubes |

Spacing between the flanges |

Tubes for venting |

Tubes term. | Tubes pour |

Capacity | Dt=150C | |||||

| mm | dm3 | m3 / h | KW | ~kg | ||||||||||

| BRH50/125 | 50 | 125 | 630 | 150 | 350 | 285 | 25 | ½” | – | 1” | 7,6 | 2,8÷4 | 70 | 21 |

| BRH65/150 | 65 | 150 | 880 | 190 | 530 | 320 | 25 | ½” | ½” | 1” | 14,0 | 6,6÷13 | 165 | 50 |

| BRH80/200 | 80 | 200 | 1180 | 250 | 700 | 380 | 25 | ½” | ½” | 1” | 35,0 | 12÷19 | 295 | 134 |

| BRH80/250 | 80 | 250 | 1380 | 290 | 850 | 420 | 25 | ½” | ½” | 1” | 63,0 | 12÷19 | 400 | 150 |

| BRH100/250 | 100 | 250 | 1380 | 290 | 850 | 420 | 25 | ½” | ½” | 1” | 63,0 | 19÷36 | 450 | 162 |

| BRH125/300 | 125 | 300 | 1650 | 320 | 1000 | 500 | 25 | ½” | ½” | 1” | 110,0 | 27÷65 | 660 | 194 |

| BRH150/400 | 150 | 400 | 2220 | 350 | 1300 | 580 | 35 | ½” | ½” | 1” | 250,0 | 47÷97 | 1170 | 281 |

| BRH200/500 | 200 | 500 | 2490 | 550 | 1500 | 680 | 35 | 1” | ½” | 1” | 460,0 | 75÷146 | 1850 | 292 |

| BRH250/600 | 250 | 600 | 2680 | 650 | 1500 | 800 | 35 | 1” | ½” | 2” | 715,0 | 105÷190 | 2610 | 304 |

| BRH300/700 | 300 | 700 | 3110 | 760 | 1750 | 950 | 40 | 1” | ½” | 2” | 1130,0 | 145÷215 | 3570 | 392 |

| BRH350/800 | 350 | 800 | 3530 | 850 | 2000 | 1050 | 40 | 1” | ½” | 2” | 1680,0 | 190÷360 | 4700 | 498 |

| BRH400/900 | 400 | 900 | 3900 | 950 | 2200 | 1170 | 50 | 1” | ½” | 2” | 2350,0 | 240÷390 | 5930 | 604 |

| BRH450/1000 | 450 | 1000 | 4030 | 1000 | 2200 | 1290 | 50 | 1” | ½” | 2” | 2980,0 | 300÷460 | 7300 | 690 |

| BRH500/1250 | 500 | 1236 | 4650 | 1280 | 2500 | 1550 | 50 | 1” | ½” | 2 ½” | 4690,0 | 460÷640 | 11160 | 855 |